Fabrication member at Blue Sky Solar Racing

2022, Dec 25

Problem

Fabricated the complete solar car, including composite chassis from tooling to layup, battery enclosures, solar panel installation, and thermoformed plastic canopy.

Process

- Designed the tooling stack-up with optimization software for minimal material waste, to be CNC-machined into the final plug shape.

- Manufactured the mold by applying an initial gelcoat layer followed by fiberglass layup over the plug surface, with extensive post-processing to achieve a smooth finish.

- Produced the final chassis components using both vacuum infusion and hand layup methods, depending on the part requirements.

- Assembled all components using reference features to maintain tight tolerances throughout the build.

Tooling board stackup of the aerobody chassis

Tooling board stackup of the aerobody chassis

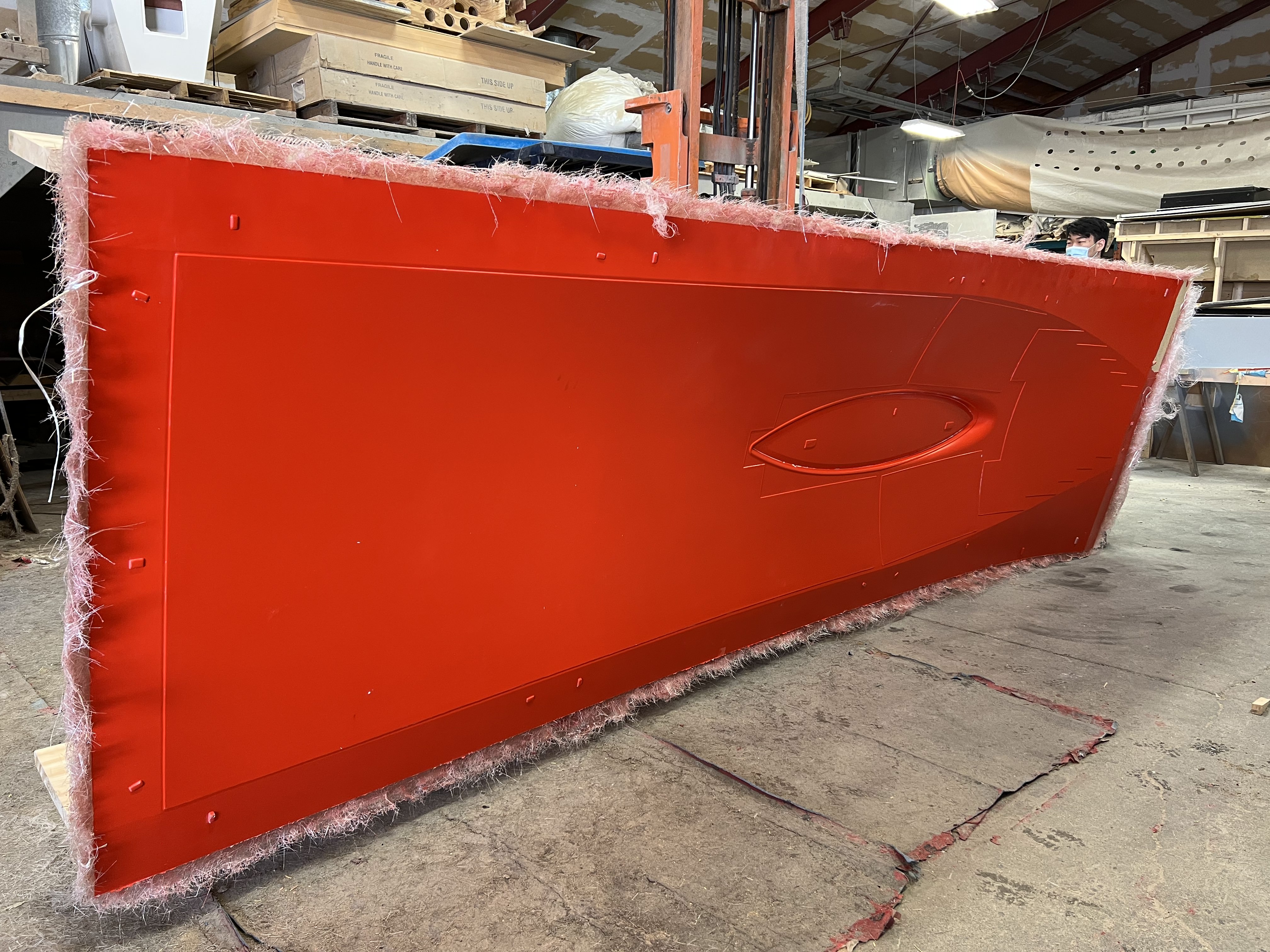

Aerobody chassis fiberglass mould with orange gelcoat layer

Aerobody chassis fiberglass mould with orange gelcoat layer

Aerobody chassis vacuum infusion with carbon fiber and Divinycell and Rohacell foam core

Aerobody chassis vacuum infusion with carbon fiber and Divinycell and Rohacell foam core

Spraying primer on the final fabricated part after post-processing to be paint ready

Spraying primer on the final fabricated part after post-processing to be paint ready

Results

The fully assembled chassis was driven for 3,000 km across the Australian outback.